Polyester Resin Plant

polyester resin production plant, Polyester resins are unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. We offer our clients a wide range of Polyester Resin Plants. We maintain high standards in our range of products.

To maintain these international quality standards, we regularly keep a stringent check on the quality of the products at varied manufacturing stages.

Polyester resins are used in sheet molding compound, bulk molding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass.

Polyester Resin Plants

(Saturated Polyester Resin Plant – Powder form)

(Un-Saturated Polyester Resin Plant – Liquid form)

Polyester Resin manufacturing Plant manufacturer

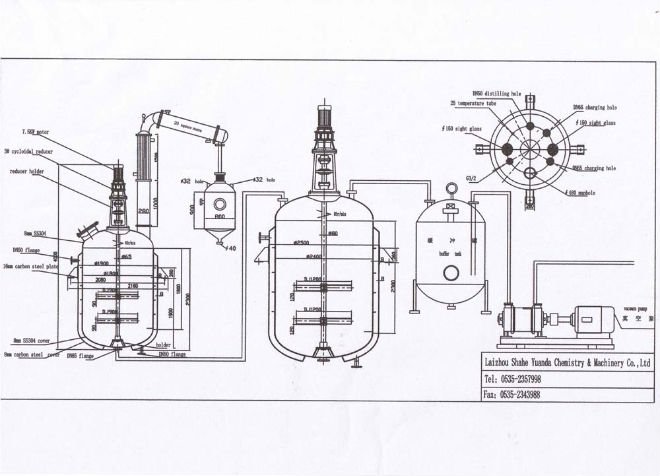

The major operations involved in the manufacture of polyester resin are esterfication and blending – which are carried in their respective kettles. The most common raw materials used are polypropylene glycol, melic anhydride and styrene monomer. In addition small quantities of inhibitors and other additives are required for the process.

The process involved is poly condensation reaction and blending the polyester resin with the monomer. Due to the sensitivity of polyester resin to contamination; in the course of condensation reaction and during subsequent handling the material of construction must be carefully selected.

Resin Plant Type

Unsaturated polyester resin production plant |

UP Resin Production Line |

powder mixer machine |

powder blender |

industrial powder mixer |

|

polyester resin production |

high speed mixer granulator |

|

high speed powder mixer |

Unsaturated Polyester Putty |

liquid dispersing machine |

unsaturated polyester resin machine |

resin production line |

chemical disperser |

Application

- 1). Resin: alkyd resin,epoxy resin,phenolic resin,acrylic resin,unsaturated polyster resin,polymer resin…..

- 2). Glue/ Adhesive:

- Hot melt glue/adhesive,white glue,silicon glue,PVC glue,PVA,PU glue….

- 3). Others: Paint,pigment,other latex,emulsion and liquid glue and adhesive.

Advantage and specification:

- 1.Material: a) kettle and cover: SUS 304 or SUS 316; b) jacket: SS304 or carton steel

- 2.Heating way: Electric heating, oil heating, steam heating or firing heating. optional.

- 3. Structure type: Outer coil heating reactor, Inner coil heating reactor, Jacket heating reactor.

Structure and Features:

Reactor consists of the reactor body, tank cover, jacket, agitator, transmission, shaft seal device and supporting.